Ferrari has revealed the production-ready chassis and powertrain of its first fully electric car, the Ferrari Elettrica, at its 2025 Capital Markets Day. The model represents a milestone in the company’s journey toward electrification, combining Ferrari’s engineering philosophy with a fully electric architecture built from the ground up. The road-going car will make its full debut in 2026.

A chassis forged from a new philosophy

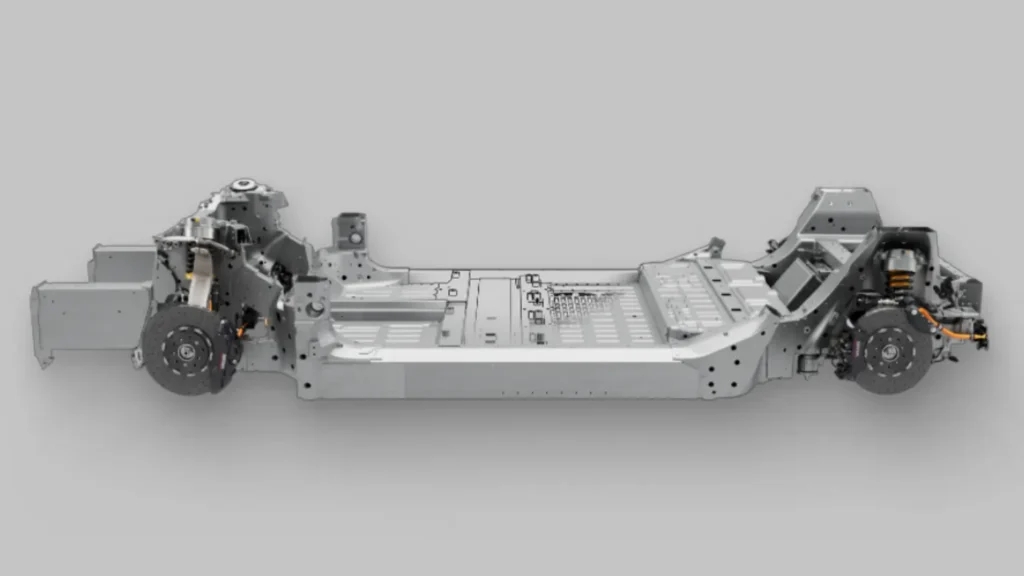

Ferrari’s engineers started with a layout inspired by mid-rear-engined berlinettas, featuring an extremely short wheelbase and a driving position pushed close to the front axle. This promises the intimate, feedback-rich connection of a focused sports car with the accessibility of a GT. While Ferrari has not confirmed the exact body type for the Elettrica, it did confirm that it will have usable rear seats, making it a four-seater.

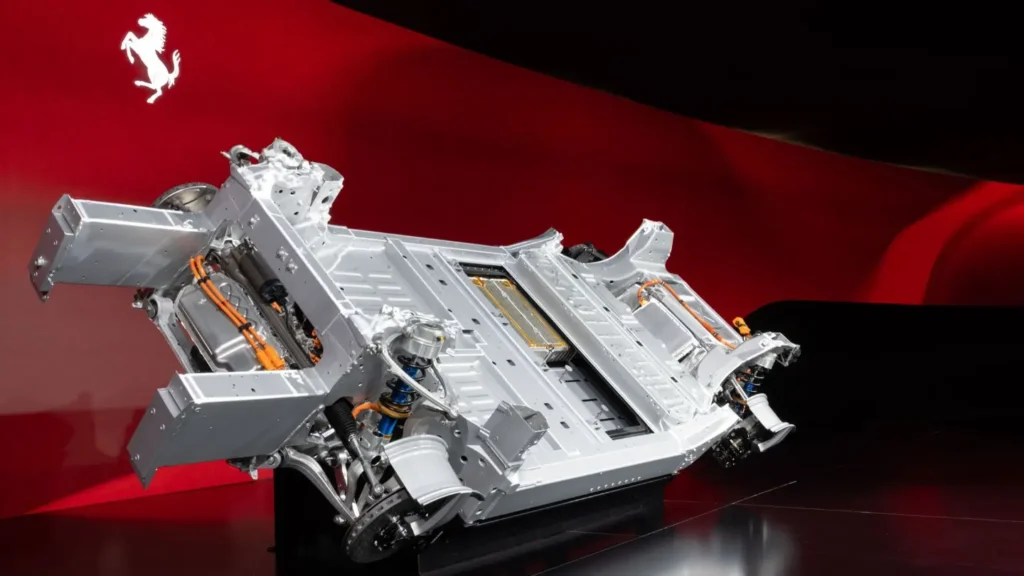

However, housing a heavy battery pack without compromising the brand’s dynamic identity required genius-level innovation. The solution was to make the battery a structural element of the chassis itself.

- Crash safety and weight saving: The front shock towers are now active participants in energy absorption. The electric motors and inverters are strategically placed to dissipate impact forces before they reach critical chassis nodes. The proprietary, patented battery pack assembly process further increases structural stiffness, and spaces between the battery modules and sills absorb energy during side impacts.

- The battery as a stressed member: The battery pack is fully integrated into the floorpan. By using the car’s own sills and bodywork as protective crumple zones, Ferrari has shaved off every possible gram, resulting in a battery-chassis system that is both incredibly light and rigid. The transverse stiffness elements are the battery’s own die-cast compression plates, which directly contribute to the car’s structural integrity.

Separate rear subframe

The rear of the car features another first for Ferrari: a separate, elasticated subframe. This is the largest one-piece hollow casting Ferrari has ever produced. Its purpose is to isolate the cabin from road noise and powertrain vibration, a common EV annoyance, without sacrificing the razor-sharp handling dynamics expected from Maranello. The active suspension system inverters are housed directly in the subframe, using their mass to further damp vibrations, while still allowing independent service of the rear axle, suspension, and battery.

Sustainable manufacturing

In an environmental step, the chassis and bodyshell for Ferrari’s first-ever electric car are crafted from 75% recycled aluminium, saving an estimated 6.7 tons of CO₂ per car.

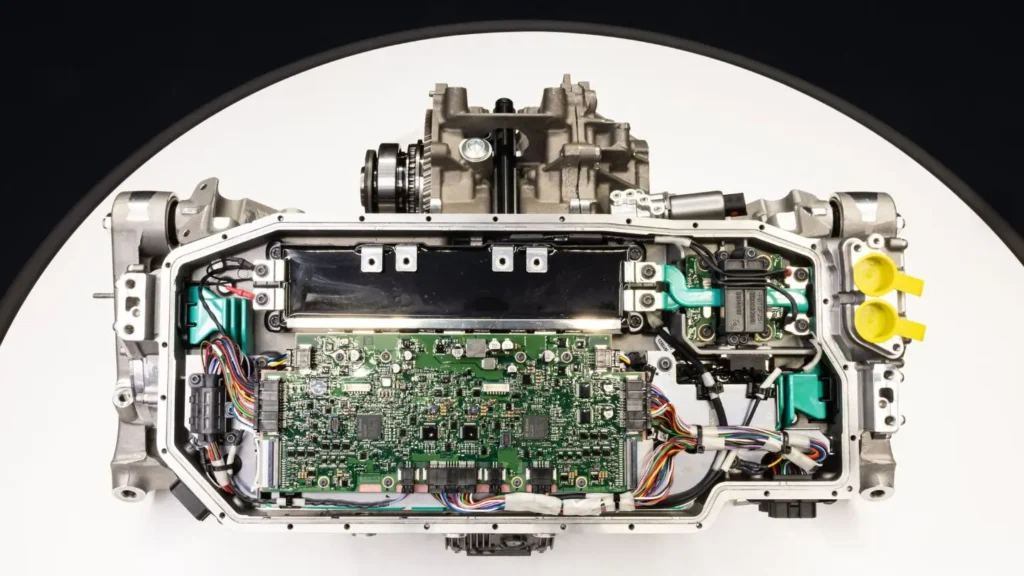

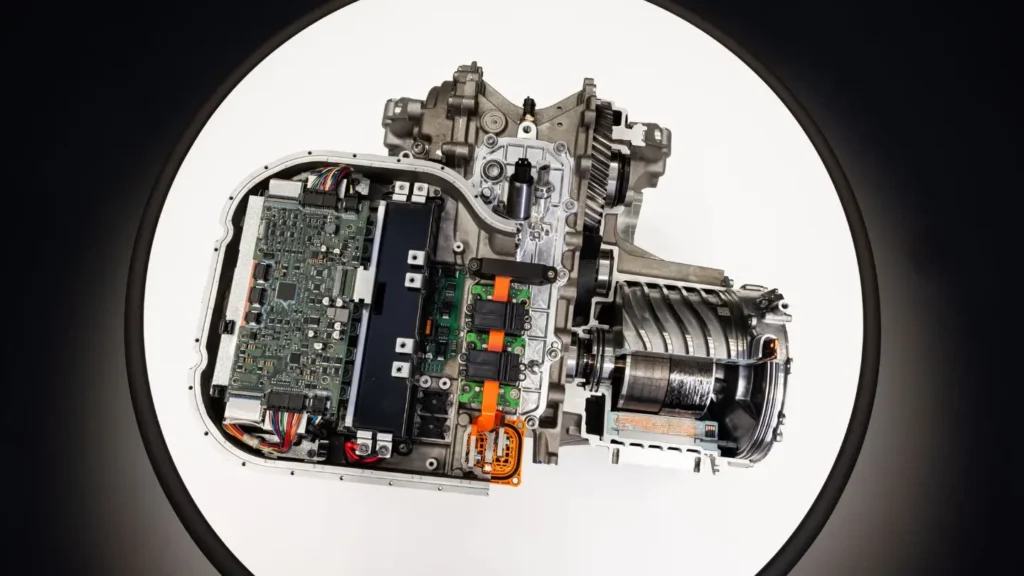

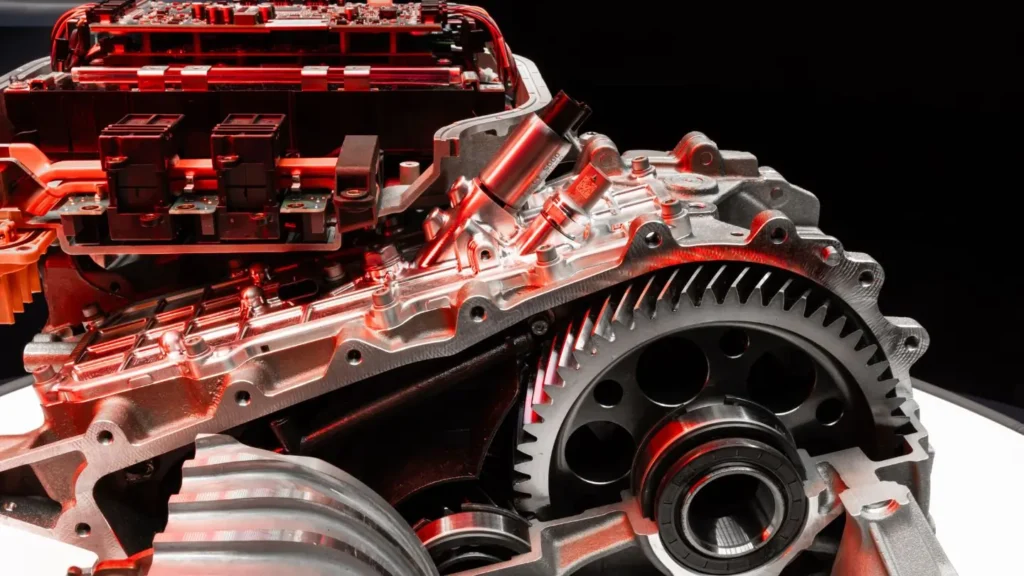

Ferrari EV powertrain: Four electric motors

Ferrari’s foray into electrification began in Formula 1 with hybridised powertrains, and that racing DNA is palpable in the Elettrica’s powertrain. The Ferrari Elettrica employs four synchronous permanent magnet electric motors, arranged as two independent electric axles (e-Axles) developed entirely in-house.

The specifications are mentioned below:

| Axle | Front | Rear |

| Total Power | 210 kW | 620 kW |

| Peak Torque | 3500Nm (At the wheels) | 8000Nm (At the wheels) |

Ferrari has not specified the combined output for its first-ever all-electric supercar, but promises over 1,000hp (over 735kW). Another clever feature for this powertrain is that the front axle can decouple from the wheels in milliseconds at any speed, transforming the Elettrica from a hyper-efficient rear-wheel-drive cruiser into an all-wheel-drive apex predator instantly.

The motors feature F1-derived Halbach array rotors, ultra-thin stator laminations, carbon sleeves to secure the magnets at extreme rotational speeds, and a Litz wire configuration to minimise losses—all contributing to exceptional torque density and high-speed reliability.

Ferrari EV battery and inverter tech

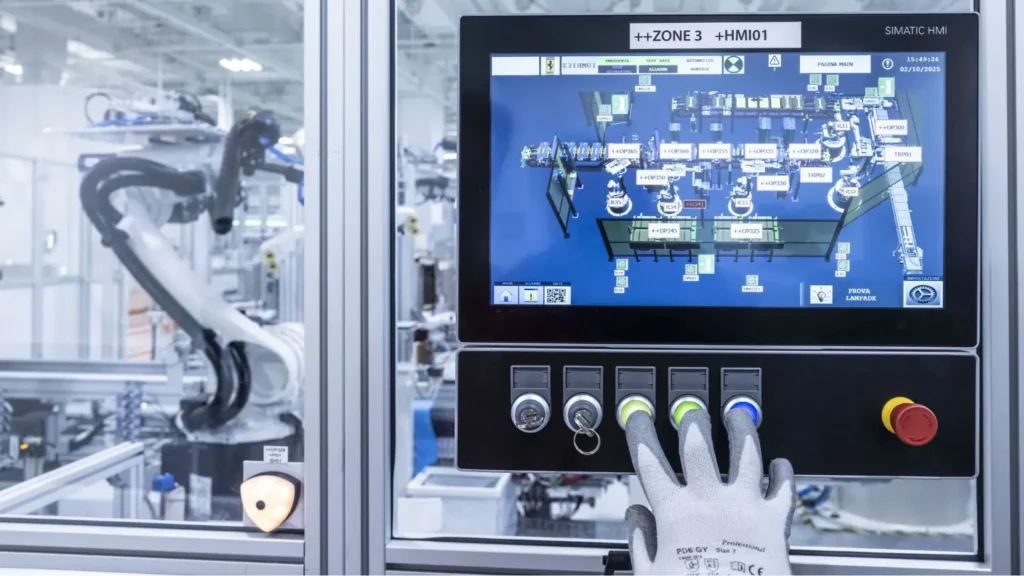

The battery and inverters for the Elettrica are designed and assembled in Maranello by Ferrari.

| Battery pack | 122kWh |

| Energy density | ~195 Wh/kg (Ferrari claims this is the highest of any production EV) |

| Claimed range | Over 530km |

| Layout | 15 modules with 210 cells in series |

| Max voltage | 880V architecture |

| Weight Distribution | An optimal 47% front / 53% rear |

| Charging capacity | Up to 350kW DC |

The battery’s placement gives the Elettrica a centre of gravity 80 mm lower than an equivalent ICE Ferrari, a fundamental advantage for handling despite the increased weight. Its modular design allows repair or replacement of individual modules or electronic components without disturbing the chassis or bodywork. The cooling system is integrated into the battery plates, which also serve as protective elements, ensuring uniform temperatures and safety under impact.

One of the primary functions of the inverters is to transform the high-voltage DC electrical energy from the battery pack into AC current to power the electric motors, and also to convert AC energy currents from regenerative braking back into DC current to recharge the battery.

The front inverter for Ferrari’s first-ever EV shares tech with both F1 and the F80, and is integrated into the front axle. This saves space and weight (just 9kg), employs Ferrari’s Silicon Carbide “Ferrari Power Pack” with six SiC modules and a sophisticated toggling strategy for improved efficiency. This grants roughly 10 km more highway range without affecting performance.

The sensory experience of a Ferrari EV: Sound and transmission

While mass-market or mainstream auto brands can look the other way when it comes to the lack of engine noise of an EV, it’s not an option for iconic performance brands like Ferrari where the engine noise is often equated as the soul of each car. This brand offers a family crossover SUV with a naturally aspirated 6.5L V12 under the bonnet.

For the Elettrica, Ferrari has rejected artificial engine noises. Instead, a high-precision accelerometer on the rear axle captures the powertrain’s mechanical vibrations. Unlike an ICE engine, where sound travels through air, the vibrations propagate through the metal components, which the system amplifies like an electric guitar to produce an authentic soundscape. This feedback is activated only when acceleration is requested or paddles are used in manual mode, offering a direct connection between the driver and the machine.

Yes, the Ferrari EV will have paddles and a manual mode. While most EVs don’t have a gearbox in the conventional sense which gives them their distinct rocketship acceleration from launch, Ferrari has not settled for the lack of driving feel in its first electric offering. If the Hyundai Ioniq 5 N can try to be fun, an electric Ferrari MUST offer more.

The Ferrari Elettrica will feature something called Torque Shift Engagement system to deliver a more involved driving experience with those electric motors. Engineers of the Italian carmaker have defined five levels of power and torque that can be selected sequentially from the right-hand-side shift paddle, shifting seamlessly from one level to another. While braking, drivers can pull the left-hand-side shift paddle to simulate progressively more intense engine braking (dropping gears). It sounds promising, but we’ll have to wait and see just how engaging this TSE proves to be.

The driving controls are equally sophisticated. Alongside the traditional Manettino for dynamics, a new eManettino on the left manages powertrain settings, including axle configuration (RWD/AWD) and maximum performance. A new Dry mode debuts on the Manettino, slotting between Wet and Sport for everyday driving.

The final EV frontier: Suspension and Tyres

So, Ferrari has figured out the chassis construction, the battery configuration, the power and a clever power delivery system for its first-ever EV. It still leaves one of the biggest hurdles for a “sporty” EV – ride and handling. The third-generation active suspension system, derived from the Ferrari Purosangue and F80, has evolved to exploit the Elettrica’s low centre of gravity. With independent control over all four wheels, combined with four-wheel steering and four independent motors, this is the first Ferrari with complete dominion over vertical, longitudinal, and lateral forces.

This holistic control allowed Ferrari to task its tyre partners with a new challenge: reduce rolling resistance by 15% without sacrificing grip. The result is a choice of five dedicated tyres, ensuring that, whether on a dry track or a wet road, the Elettrica’s contact patches are as advanced as the powertrain that connects to the asphalt.

Ferrari Elettrica debut and launch

Production of the Ferrari Elettrica is expected to begin in 2026, with a full public reveal, including the distinctive electric sound experience, scheduled for Spring 2026. Unlike the current crop of EV hypercars, namely, the Rimac Nevera, BYD Yangwang U9, and Lotus Evija, the first-ever Ferrari EV will be more practical by comparison.

Comments

New Comment